By Dr Deepak Halan

When chargers embedded into the roads become a commercial viability, the impact would be revolutionary and crucial for autonomous cars of the future. Instead of taking the EVs to the charger every few hours, these would be constantly charged from the road as they drive along.

An electric car being charged using a cable (Credit: www.pocket-lint.com/cars)

In conventional cars, travelling a long way is not a problem with easy and quick refuelling. However, in today’s electric cars, extended journeys require careful planning to ensure that the battery is fully charged at the starting point and that compatible fast-charging stations are available en route. It would be much more convenient if batteries could be recharged wirelessly while travelling on the road so that no break for recharging is necessary.

Consider a future scenario wherein, as you exit a building, a driverless ridesharing electric vehicle (EV) pulls over, takes you to your destination and then proceeds to drive passenger after passenger, without ever stopping to recharge its battery. Instead, the renewable power generated by nearby wind or solar resources is delivered wirelessly to the roadway to recharge while the EV is moving.

Not needing to stop for recharging will make EVs truly autonomous, enabling them to remain in service for more hours, and thus fewer vehicles will be needed to meet the same passenger demand. Also, their batteries could be made much smaller, leading to reduced costs and increased adoption. Basically, wireless vehicle charging, much like placing a smartphone on a charging pad instead of plugging it in, charges the battery when the car is parked over a charger pad placed on the ground below. This means no bulky cables need to be lifted out of the boot of the vehicle.

In fact, there is no requirement of cables in the park and charge system. The drivers simply need to pull into a parking space to charge the batteries, start and end the charging using their smartphones, and pay for the services rendered using an app. Inductive charging based on electromagnetic induction is used to charge the EV batteries wirelessly, much like the other electric devices with wireless charging facility, such as mobile phones, electric toothbrushes, etc.

In inductive charging, electric energy gets transferred through an air gap from one magnetic coil to another when the two coils are aligned with each other. An alternating current from an external source is made to flow through a coil to create a varying magnetic field, which then using electromagnetic induction generates alternating current in the other coil placed close to it. Rectifiers are used to convert this alternating current into a direct current to recharge the batteries.

History

Wireless charging technology has been around since the late 19th century when Nikola Tesla demonstrated magnetic resonant coupling—the ability to transmit electric energy through the air by creating a magnetic field between two circuits. The technology was first used by Hutin and Le-Blanc in 1894 to power an electric vehicle. For about hundred years the technology did not draw much attention, except perhaps for application in a few devices such as electric toothbrushes. The emphasis was on improving the performance of the internal combustion engines which were in extensive use in the vehicles, and no attention was paid towards this technology.

In 1972, Professor Don Otto of the University of Auckland revealed an electric vehicle powered wirelessly by using transmitters placed under the road and a receiver on the vehicle. In 1977, Trombly patented an electromagnetically coupled battery charger to charge headlamp batteries for miners. The real breakthrough came in 1978 when the US engineers Bolger, Kirsten, and Ng created an electric vehicle using a 180Hz wireless charging system with 20kW power.

In California, in the 1980s, inductive charging was used to power a bus, and similar work was done in France and Germany around this time. In 2006, MIT demonstrated transmission of a large amount of power over a few metres using resonant coupling. In 2007, MIT physics professor Marin Soljačić displayed wireless transfer of electricity at two metres with much improved efficiency. Soljačić established WiTricity to commercialise the technology.

The first wireless chargers appeared in the market about six years ago using tightly coupled inductive charging in which the device is required to be placed in an exact position on a pad to charge. The world’s first complete hands-free plugless proximity inductive charging system for electric vehicles, Plugless Power, was brought by Google from Evatran in 2011 for their electric vehicles to transport employees. In November 2011, the Mayor of London, Boris Johnson (now the prime minister of the UK) carried out a trial on fifty EVs using thirteen wireless charging points.

In October 2014, the University of Utah added an electric bus to its fleet that used an induction plate at the end of its route to recharge the batteries. In January 2015, Hughes Electronics developed the Magne Charge interface for General Motors and Toyota; AUDI presented a 3.6kW inductive charger during the 66th International Motor Show, and in Germany, Bombardier-Transportation presented a 3.6kW wireless charger for cars. Charging pads became commercially available in high volume in 2015.

Recently, the researchers at the Korea Advanced Institute of Science and Technology (KAIST) developed an electric transport system, called Online Electric Vehicle (OLEV), where a power source is placed underneath the road surface and power is wirelessly picked up by the test vehicles, moving on the power track in a convoy formation to avoid traffic congestion.

Today, there are nearly half a dozen wireless charging technologies available commercially, making inroads in the smartphones, automotive, healthcare, and manufacturing sectors with the promise of increased mobility. However, charging across a room as a commercial high-volume reality is still at least a year away.

How wireless charging works

Wireless electric charging for vehicles works quite like wireless smartphone charging, just that it is on a bigger scale—the distance being in centimetres instead of millimetres. Electric energy is transferred through an air gap from a magnetic coil in the charger to another magnetic coil fitted on to the car, when the car is parked such that the coils are aligned.

The wireless chargers are mainly of three types: chargers with charging pads that use tightly coupled electromagnetic inductive or non-radiative charging; charging bowls or through-surface type chargers that use loosely-coupled or radiative electromagnetic resonant charging; and uncoupled radio frequency (RF) chargers with trickle charging capability at distances of a few feet.

Basically, all the three operate on the principle of electromagnetic induction in which a magnetic coil (called transmitter) is used to create a time-varying magnetic field. The magnetic field induces an alternating current in coils of wire (called receiver) placed in that magnetic field and electric energy gets transferred from the transmitter to the receiver through inductive coupling. Resonant charging (also called magnetic resonance) is used in charging bowls in order to increase the induced current to transmit power efficiently across greater distances. Appropriate capacitances are added to the transmitter and receiver coils, so that they resonate at the frequency of the time-varying magnetic field.

To minimise the weight and decrease the skin effect resistance, a movable transmission coil mounted on an elevating platform and receiver coils made of silver-plated copper or aluminium are used. The distance over which the power can travel also depends on the size of the coils used. The bigger the coil, or more the number of coils, the greater is the distance the charge can travel. In EV chargers, the coils used are of much larger diameter so that energy gets transferred over greater distance, in comparison with smartphone wireless charging.

Wireless charging systems

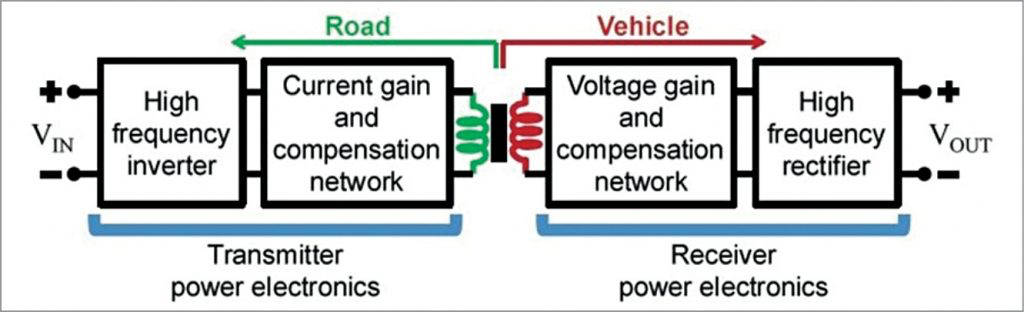

The wireless power transfer systems are of two types: inductive—which use magnetic field coupling between conducting coils, and capacitive—which use electric field coupling between conducting plates to transfer energy. The inductive system uses a transformer for electromagnetic coupling whereas a capacitive system uses a network with inductors and capacitors for the coupling. Electronic circuits, consisting of semiconductor rectifiers, high-frequency inverters, and gain and compensation networks are used in both the systems to convert the alternating current into direct current to charge the batteries.

Block diagram of a typical inductive wireless power transfer system (Credit: www.ncbi.nlm.nih.gov)

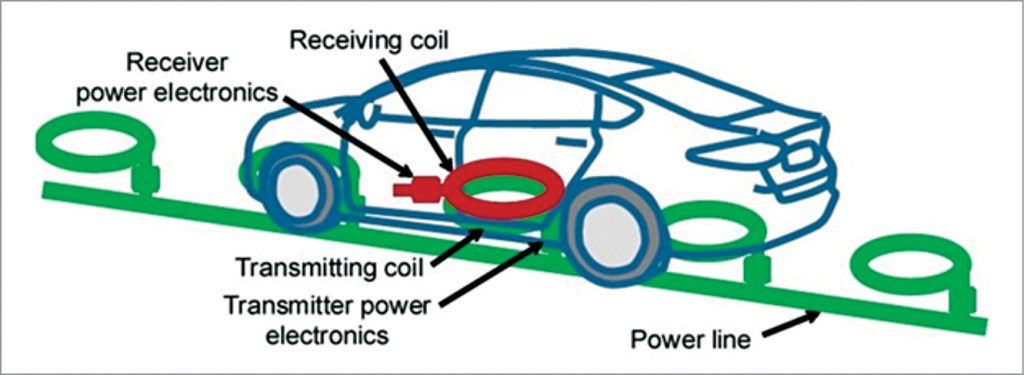

Inductive systems are preferred for medium-range static charging systems, where the distance between the transmitters embedded in the roadway and the receiver fitted on the electric vehicle is comparable to the size of the couplers. Stationary chargers using inductive charging are already available in the market for use in cars. A few manufacturers are planning to introduce the built-in stationary inductive charging systems in their high-end cars.

The inductive system physically implemented in an EV (Credit: www.ncbi.nlm.nih.gov/books)

In dynamic systems, where a truly short time is available when the vehicle is passing over a charging coil, high power transfer density capability is required to deliver the required energy to the vehicle during this time. For this reason, the dynamic power transfer systems have not been commercially viable, although a few experimental systems have been demonstrated.

Operating frequency

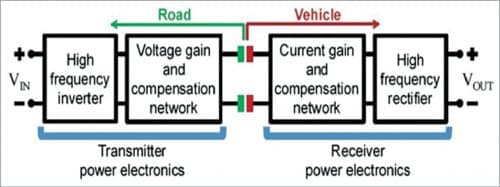

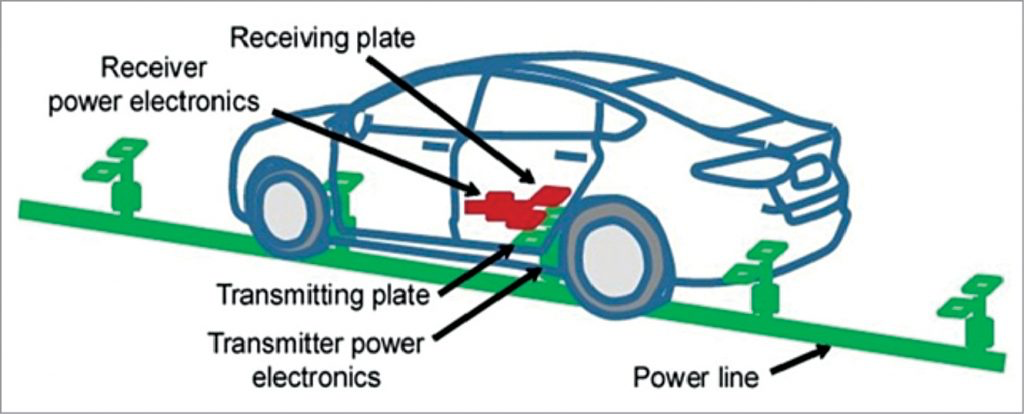

Designers prefer capacitive wireless charging systems, which operate at higher frequencies, so that energy storage requirement is decreased, allowing smaller power electronics to be fitted. This makes it possible to reduce the size of the couplers and increase the power transfer density and displacement current.

Block diagram of the capacitive wireless power transfer system (Credit: www.ncbi.nlm.nih.gov/books)

The operating frequencies are kept below 100kHz in the inductive systems to minimise losses in the ferrite cores that are used for magnetic flux guidance and shielding. This results in larger coils and lower power transfer densities, making them bulky.

Ferrites are not required in the capacitive systems as the directed nature of electric fields greatly reduces the need for electromagnetic field guidance and shielding. The system can be operated at frequencies higher than 100kHz, allowing the size to be reduced. At higher operating frequencies the losses increase and achieving high efficiency becomes a challenge.

Physical implementation of a capacitive system in an EV (Credit: www.ncbi.nlm.nih.gov/books)

Ensuring human safety

Humans and animals may be present in the vehicle cabin or immediate vicinity of the perimeter of the chassis. They need to be protected against the electromagnetic radiations. For this purpose, the fringing electromagnetic fields of the system are required to be maintained within the safe levels laid down by the International Commission on Non-Ionizing Radiation Protection (ICNIRP 1998).

In capacitive systems the requirement is met by designing circuit stages to optimise voltage and current gain and by using reactive compensation. Other approaches used by the designers include employing field-focusing phased-array multiple phase-shifted capacitive modules and minimising the fringe radiations by beam forming.

Optimising power transfer

The systems are designed to operate close to the resonant frequency of the coupler reactance and the compensating network to optimise power transfer. The coupler reactance depends on the vehicle’s road clearance and varies as the vehicle moves on the road across the charger, causing drift between the operating and resonant frequency. The drift causes a reduction in power transfer and system efficiency.

To maintain the resonant frequency unchanged as the transmitter and receiver move relative to each other, the preferred technique is to use high-frequency rectifiers and inverter compensation architectures. They compensate for coupling variations to maintain the operating frequency at a fixed level. This ensures that the output power of the system is maintained at a fixed level across wide variations in coupling and is applicable to both capacitive and inductive systems.

For systems operating at frequencies below 100kHz, the frequency band is not a restriction and the systems can be designed such that the operating frequency tracks the resonant frequency. In high-frequency systems this is not feasible as the operating frequency has to stay within the designated industrial, scientific, and medical (ISM) bands.

Wireless charging systems available

There are basically two types of charging systems—static and dynamic.

Static charging systems. Several static charging systems are now available. BMW is providing a wireless charging pad for its electric car 530e iPerformance. The pad can be connected to the power outlet in the garage to charge the car wirelessly. About 3.5 hours are normally required to fully charge the 9.5kWh battery of the car.

Wireless chargers for Tesla Model S, BMW i3, Nissan Leaf, and first-generation Chevrolet Volt are readily available in the market. The cost of these chargers varies from $1,260 to $3,000. These can enable 40km to 80km of per hour of charging, depending on the system used.

Another wireless charging system called Plugless System available in the market includes a charger that rests on the floor, and a power receiver that is attached to the car. The receiver can be removed when one wants to keep the charger while disposing of the car.

Another wireless charging system available in the market is the Halo system, which is becoming increasingly popular with the electric emergency cars deployed for Formula E races. The system keeps the batteries of the BMW i3 medical cars and i8 safety cars topped up during each race day. Since the cars are not required to be plugged in, no valuable seconds are wasted when the cars are needed out to attend an emergency on circuit. This time saving is crucial for electric ambulances and other emergency vehicles.

IN2POWER, a Belgian innovator, has recently brought out 1.1kW to 16kW ‘plug & play’ wireless charging systems (combinable up to 48kW) for autonomous guided vehicles, drones, medical and naval applications to charge batteries with 30A to 750A current with 95% efficiency. Wiferion, a German company, has made available commercially a 3kW wireless charging system for industrial applications with an overall transfer efficiency exceeding 90%.

Dynamic charging systems. The crowning glory of the wireless charging technology is its ability to power a car traveling at speeds as high as 110 kilometres per hour as it drives over chargers embedded into the surface of the road.

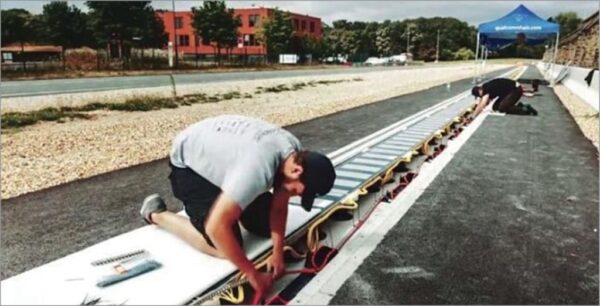

Qualcomm has developed a system, called Dynamic Electric Vehicle Charging (DEVC), in which a wireless charging system is installed underneath the surface of a 100-metre test track, to provide charging power to a fleet of specially modified electric vans, each fitted with two 10kW charging pads. At a time, several vehicles can be driven along the road, each taking a small amount of energy from each charger as they drive by. Though the batteries do not get fully refilled, they essentially do not lose any power while using the road and the stored energy is saved for an unpowered road. The system is robust as it does not get affected by bad weather and works equally well when the track is covered with water.

Qualcomm DEVC system being installed underneath the surface of a test track (Credit: www.qualcomm.com)

Qualcomm is experimenting fitting DEVC under the surface of the racing track of a Formula E circuit. The drivers would have to decide between taking the faster conventional racing line or a longer DEVC fitted route where no stoppage is required for topping up batteries.

When chargers embedded into the roads become a commercial viability, the impact would be revolutionary and crucial for autonomous cars of the future. Instead of taking the EVs to the charger every few hours, these would be constantly charged from the road as they drive along. When the dynamic wireless charging systems become a commercial viability, it would be a crucial milestone for autonomous cars of the future as these would be constantly charged while driving.

Application areas

Applications of wireless charging can be divided into two broad areas: low power and high power. Low power applications generally include small consumer electronic devices such as cell phones, handheld devices, small computers, and other devices that need charging at power levels below 100 watts. High power wireless charging refers to charging at power levels above one kilowatt.

Power levels of the charging systems that use resonated primary and secondary coils range from 1kW to 300kW. Their most significant application area is in electric EVs, but it is not limited to EVs.

Recently, Japan-based robot manufacturer Daihen has developed a wireless power transfer system for automatic guided robots. Using this wireless charging system, the robots simply need to pull up to a wireless charging area to power up and then go about their duties.

Wireless charging is increasingly finding application in the medical sector as well. The technology enables long-term charging of implants and sensors located beneath the skin. It has been possible to print wireless power transmitting antennas on flexible materials placed under the skin of patients. These under-skin materials enable monitoring the patient status over a longer period, leading to a more detailed diagnosis by the doctors.

Advantages of wireless charging

Newer trends in wireless charging technology are making available more efficient and compact charging systems. These systems use ultra-thin coils, higher operating frequencies, and optimised drive electronics to reduce the transfer losses. The systems can be easily integrated into the mobile devices or batteries.

The major advantage of wireless charging is that there is no possibility of electric shock, as there are no exposed conductors. Some other advantages are:

• Wireless charging at high power levels enables charging of EVs while in motion, consequently extending the driving range

- Provides higher reliability as the charging systems are operated automatically without dependence on people to plug, unplug, and operate

- Less likelihood of electrical faults, such as short circuits

- Protection against danger of corrosion as circuits and devices are enclosed, providing shield from water and oxygen in the atmosphere

- Significantly less wear and tear as there is no need to constantly plug and unplug the device, providing greater durability

- Increased convenience and aesthetic quality as no cables are used

- Low infection risk for embedded medical devices as transmission of power via a magnetic field passing through the skin precludes the infection risks associated with wires piercing the skin

However, the inductive wireless charging systems using low power (less than 100 watts) may have the following disadvantages:

- Due to the slower charging and lower efficiency, the devices take longer to charge with the same supplied power

- Drive electronics and coils used in the charging device increase the complexity and cost

- Most of the mobile devices, when connected to a cabled charging system, can be moved around (in a limited range) and can be operated while charging. Whereas, in most of the static wireless charging systems, the mobile device must be left on a pad to charge and cannot be moved around or easily operated while charging

Standards for wireless charging

Several organisations worldwide formulate standards for inductive charging. The Wireless Power Consortium (WPC) established in 2008 created the Qi (pronounced “chee”) standards in 2010, which became the most popular standards—covering inductive charging and short-distance (1.5cm or less) electromagnetic charging.

Japan established Broadband Wireless Forum (BWF) in 2009 and the Energy Harvesting Consortium (EHC) was founded in Japan in 2010. Korea established the Korean Wireless Power Forum (KWPF) in 2011. In 2012, the Institute of Electric and Electronic Engineers (IEEE) initiated the formation of the Alliance for Wireless Power (A4WP) and the Power Matter Alliance (PMA). The Wireless Power Consortium for Practical Applications (WiPoT) was formed in 2013.

In 2018, The Qi Wireless Standard was adopted for use in military equipment in North Korea, Russia, and Germany. The WPC, a 296-member consortium, included Apple, Google, Verizon and several other leading electronics manufacturers.

In 2014, the PMA formulated inductive charging specifications—Powermat for the technology used for wireless charging in coffee shops and airports. The Starbucks started using Powermat in 2015 for their nearly 8,000 coffee shops.

The A4WP and the PMA joined together to form the AirFuel Alliance (AFA), which now has 110 members including Dell, Duracell, Samsung, and Qualcomm. Duracell has more than 1,500 charging spots in the US and 1,000 charging spots in European airports, hotels, and cafes using AFA standards.

The two main standards, Qi and AFA, are quite similar but use different transmission frequencies and connection protocols. Hence, the devices compatible with one standard are not necessarily compatible with the other standard. However, devices compatible with both the standards are available.

An emerging standard is SAE J2954, which covers inductive car charging up to 11kW. ISO 15118 for Vehicle to Grid communication is an internationally adopted standard issued recently by the International Organization for Standards (ISO), Geneva.

Conclusion

High-performance, safe, and cost-effective EV wireless charging has the potential to revolutionise road transportation. The capacitive and inductive charging systems both offer enormous opportunities for research, especially in designing high-frequency power electronics and near-field couplers. Some of the significant areas needing further research are the effects of long-term human exposure to electric and magnetic fields; methods to detect living and foreign objects in the proximity of the systems; optimal charging power levels and air spacing for cost-effectiveness; cost-effective technology for embed charging roadways; and impact of system deployment on the electric grids. Research and experimentation are currently underway in these fields.

High initial costs associated with installing and using the infrastructure for dynamic wireless charging systems are a big hurdle, more so as this would benefit only EVs, a small percentage of the total vehicles currently on the road. Another problem is the methodology to be adopted for computing the energy consumption of each vehicle while charging from the lane.

The other related issues needing attention are: eliminating or controlling safety hazards associated with the large amounts of heat and other electromagnetic radiations produced between the charging surfaces. For example, the safety hazard faced by a person with an implanted pacemaker travelling inside the EV. Another downside is the need for precise alignment between the inductive pick up and the charging facility.

A beginning has been made and wireless charging systems are already available commercially. Smartphone manufacturers like Apple and Samsung have already started adding this technology into their high-end devices. The wireless charging technology developed for charging of electric vehicles has potential for very wide application in wirelessly powered biomedical implants, humanoid robots, and supersonic hyperloop transport.

The technological challenges in these fields are exciting and the possibilities endless, as numerous problems related to performance, cost, and safety need to be overcome before the vision of wirelessly powered EVs can be finally realised. Professor Herbert Kohler, Daimler’s Future Mobility Head, has predicted that the wireless charging for EVs may become available for common use after 2026 only, when all the associated aspects have been investigated.

Dr Deepak Halan is associate professor at School of Management Sciences, Apeejay Stya University

ELECTRONICS FOR U

Leave a Reply

You must be logged in to post a comment.